dentist dental supply

Type of dental burs for dentist and dental technician

Dentist and dental lab burs

Dental burs are used to cut the hard and soft surfaces of the teeth and other dental materials. The dentist used them to prepare the endodontic cavity. The burs provide a strong fitting to the endodontic handpiece and are used during filling and root canal procedures. Variations in dental bur forms and shapes make them special for any dental procedure. The choice of dental bur depends on the location and nature of the cavity. More than one dental bur can be used in a single dental procedure. The selection of dental bur depends on the size and nature of the cavity. More than one dental bur can be used in a single dental procedure. The dental bur used in the dental lab is tougher and more flexible in shaping and cutting. They were used to cut hard plastic, model trimming, and crown preparation. The thickness of dental lab burs is specific and the advanced cutting edge is different for each technique. Nizagara http://www.pharmacynewbritain.com/nizagara/

Types of dental burs

Three basic types of dental burs keep variation in structures and function.

- Shank

It gives the fitting surface in the dental handpiece. There are three different shank styles are available for dental burs. In the dental lab bur, the shank is attached with the high-speed motor while in the dentist bur the attachment is slow of the high-speed handpiece.

1, Friction Grip (FG)

A small cylindrical shank that fits into a handpiece and builds a strong attachment surface. It is used for both carbide and diamond materials. A high-speed handpiece is best suited for friction grip shank style. The sizes of FG diamond burs are available in a very flexible range.

2,Right Angle (RA)

It is also referred to as the Latch-Type shank design of the dental bur. One side of the shank is straight, while the other has a latch attached to the piece of the hand. Both the slow pace and the contra-angle handpiece were ideal for the right angle. The length of the shaft is around 20mm. The nature of the latch type is ideal for carbide and diamond bur.

3, Handpiece (HP)

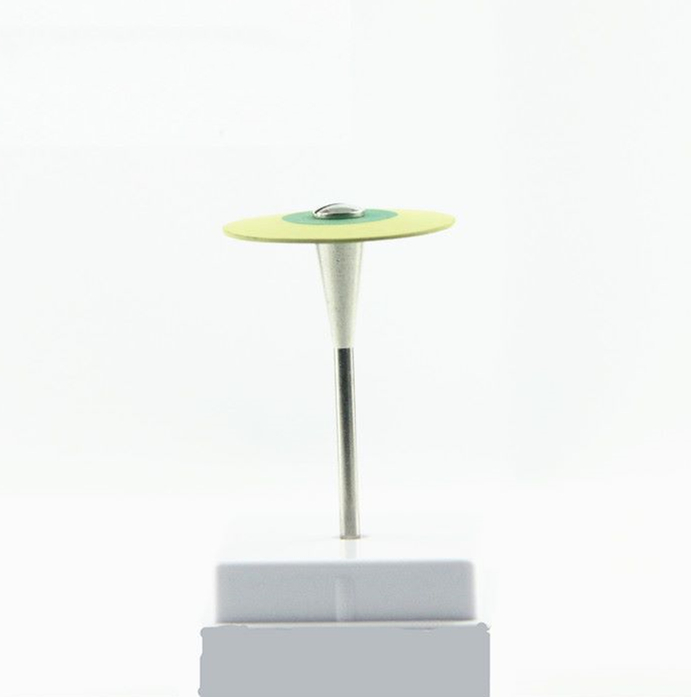

The other name is a straight handpiece design. The shank is cylindrical and straight. Diamond cutting disc head is most widely found in long straight piece shanks. The slow-speed handpiece gives the best cutting quality.

- Neck

The neck attaches the shank to the head of the dental bur neck and also has a color-coded band that is special for every bur.

- Head

Head’s got the cutting edge of the burs. The shape of the head determines the burs’ form. It is the key feature of a dental bur that has a grit-specific pattern and a distinctive shape. Head of diamond burs have cutting grooves that offer an effective cutting surface, there are a variety of types of bur heads that are used according to their purpose. The flutes on the cutting edge were positioned at different angles specified for the special cutting procedure. Buy Phentermine online http://kendallpharmacy.com/phentermine.html

- Roundhead

A round, small dental bur is used to cut hard and soft teeth surfaces. The dental dentine was also removed. Helps to create access points, and to create extension channels in restorative cavity procedures. The round head is also available in various shank designs and sizes as needed by the dentist.

2. Straight head

A straight head gives the parallel surfaces of cavity walls. The material used is normally Dimond and height and length vary with the cavity design.

3. Inverted conehead

It gives the undercuts in the floor of the dental cavity. The shape provides ease of cavity preparation in endodontics procedures. The head design is available in diamond and carbide material.

4. Tapered fissure head

The head has a tapered finishing and is used in endodontic procedures and is available in short and long head sizes and lengths. In the dental lab burs its available in different sizes of tapers.

Taper shank of carbide burs dental lab is the application of laboratory finishing and polishing dentures on acrylic, cobalt chrome dental restoration, die stone dental lab model production process, etc.

5. Pear-shaped head

It is used in cavity finishing and after filling for the removal of excessive dental filling material. The versatile shape is used for cavity design, dividing the roots of the tooth, and creating new access points.

Types of dental burs material

The different material is used for dental burs.

- Stainless steel burs

Stainless-steel dental burs are used to cut rough objects. It offers the best cutting surface and has a long working life. The hard texture of burs may also be used to remove previously placed dental filling material. Extremely immune to breakage, so more economical than other dental burs. The pattern of the steel bars is lacquered in the right-angle handpiece.

- Tungsten carbide burs

It can be used for initial tooth cutting and dental crown removal and restoration. The material is stiffer than the steel material. It is commonly used as a dental lab bur. Strong acrylic content can be trimmed with carbide burs. They are resistant to wear and tear. They are also available with coated heads that increase cutting efficiency. Burs handling is simple and has a long working life in the dental lab.

- Diamond burs

Diamond bur is still the most common form of dentist dental lab bur. Diamond has variations in cutting grits that make it a suitable dental bur. They used a high-speed handpiece in a friction grip shank style. The fine cutting grit is easily dull with time, so a change of bur is needed for excellent cutting. The rough bur quickly cuts the surface of the enamel without any polishing surface. It’s available in all shapes and sizes.

- Finishing and polishing burs

Frequently used for the finishing of composite filling materials. The burs have a distinctive angle of rank and the finishing head. Various sizes and shapes are available in dentist dental material that gives an excellent cavity finish. The polishing burs have a shining surface for a dental filling. Color codes are special for each dental procedure.

Zirconia ceramic dental lab burs are an excellent dental lab polishing device. Accessible in fine, medium, and straight cutting heads, this rendered it resistant to high temperatures during the polishing process. Zirconia burs are durable and have excellent cutting capabilities.

Laboratory dental silicon rubber burs polish dental plaster, glass, dental porcelain, and hard metal alloy finishing. Hardness and toughness avoid fatigue and breakage. Accessible in various color coding and each color determines the thickness of the grits.

Dental acrylic laboratory burs

Dental acrylic laboratory burs are used to treat acrylic materials such as partial and complete dentures, custom trays, rough gold abrasion, cobalt-chromium dental alloys, composite veneers, or ceramics before the final firing. Acrylic dental burs are manufactured of the finest quality stainless steel for longevity and precise cutting. It decreases the amount of rework. It also demonstrates a convincing cutting performance and an impressively long service life.

The color-coding system of dental burs

Dentists and dental lab burs have a special cooler coating on the neck that defines the cutting characteristics of dental burs. Dental bur coarseness determines the cutting strength of dental burs.

The black band is for super coarse, green for coarse, blue for medium, and red and yellow for fine and superfine burs. The coarse head is more suitable for cutting objects, and the fine head offers excellent surface finishing and polishing.

In 1979, a specific numbering system was introduced by the international standards organization for dental burs. They give the 15-digit code that is divided into 6 parameters with 3 digits of each code.

The first 3 unique for the material and cutting edge of the bur. the second 3 digits are for the shank design of burs, and the next 3 digits are for the specifications for the length of the total bur. The fourth dight code unique diamond grits. The fifth pair represent grit finesse and coarse surface the and last three codes for bur head diameter.

Dental milling tools: with the technology of cad cam dentistry and optional dental milling system, there are various of cad cam dental milling burs for choice: milling system, application of dental zirconia blocks, lithium disilicate blocks, pmma dental blocks, cobalt chrome dental blocks, etc.

For the complete specification of burs dental details, please take a reference of the following link in the dental supply online store.

- Dental lab burs

https://www.dentallaboratorio.com/product-category/dental-lab-burs/

- Contra angle series

https://www.dentallaboratorio.com/product-category/dentist-dental-supplies/contra-angle-burs-dental/

- FG shank series

https://www.dentallaboratorio.com/product-category/dentist-dental-supplies/fg-carbide-burs/